Alpma: innovation in the cheese industry

ALPMA Alpenland Maschinenbau GmbH has been a leader in mechanical engineering for the cheese industry for 76 years. From production to processing, the company provides innovative and efficient solutions. When building a new production facility, Alpma was looking for a way to thoroughly clean cheese moulds to meet the strict hygiene standards in the dairy industry.

Alpma needed a reliable and efficient washing installation that not only cleans thoroughly, but also contributes to a streamlined production process. Thanks to previous successful collaborations with Supura, they knew they could count on a durable and effective solution.

- Customer: Alpma

- Year: 2023

- 350 moulds per hour

What we did

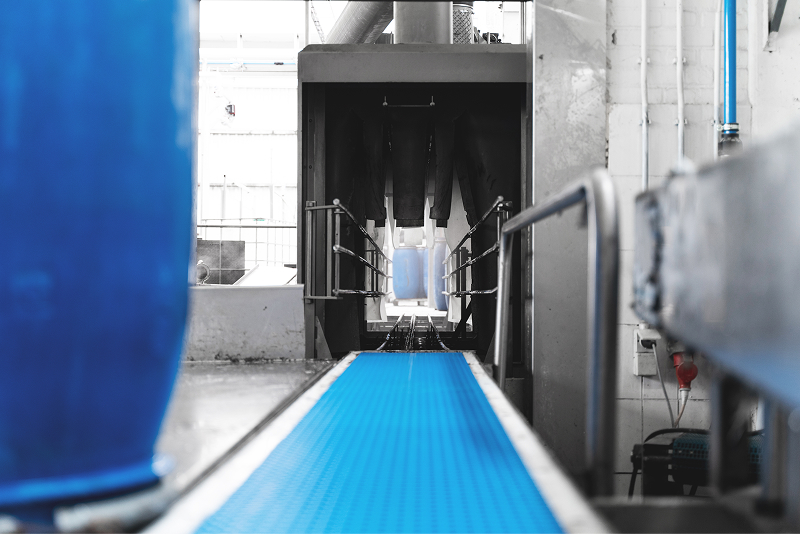

A specialised form washer for maximum hygiene.

Together with Alpma, we developed a tailor-made mould washer that fits perfectly into their production process.

Our solution:

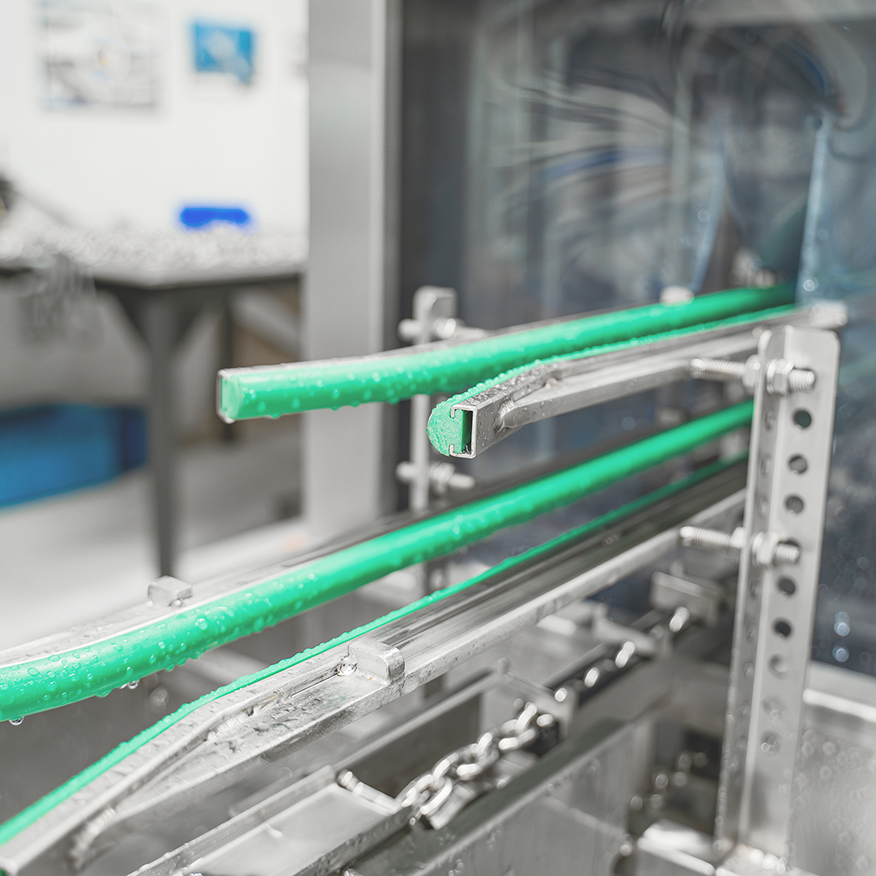

- Optimal cleaning: thorough removal of residues and bacteria.

- Efficient water and energy use: sustainable design with minimal waste.

- User-friendly and reliable: smooth maintenance and minimal downtime.

By integrating this machine into their production line, Alpma can guarantee hygiene and keep production running uninterrupted. The result: a streamlined process with consistently clean cleaning results.

The pure outcome

With the new form washer, Alpma meets the strictest hygiene standards and increases the efficiency of the cleaning process.

- Reliable cleaning: consistent quality and minimal manual intervention.

- Optimised productivity: no delays due to inefficient cleaning.

- Sustainable choice: a solution that saves energy and water without compromising effectiveness.

Alpma continues to look ahead and invest in innovation. Choosing Supura confirms their commitment to sustainable and high-quality technologies.

More cases

Detailresult

More efficient cleaning and double capacity at Detailresult